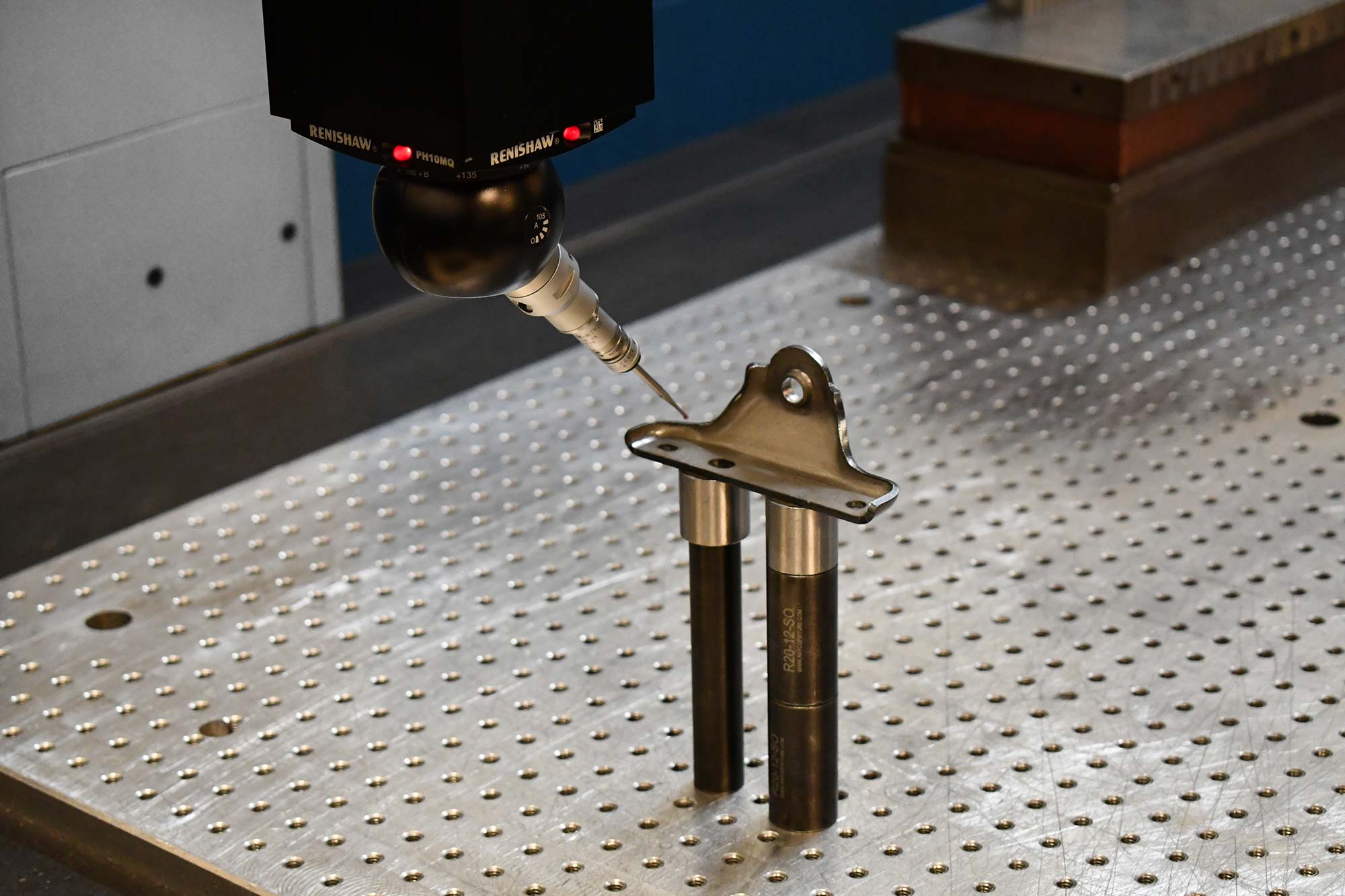

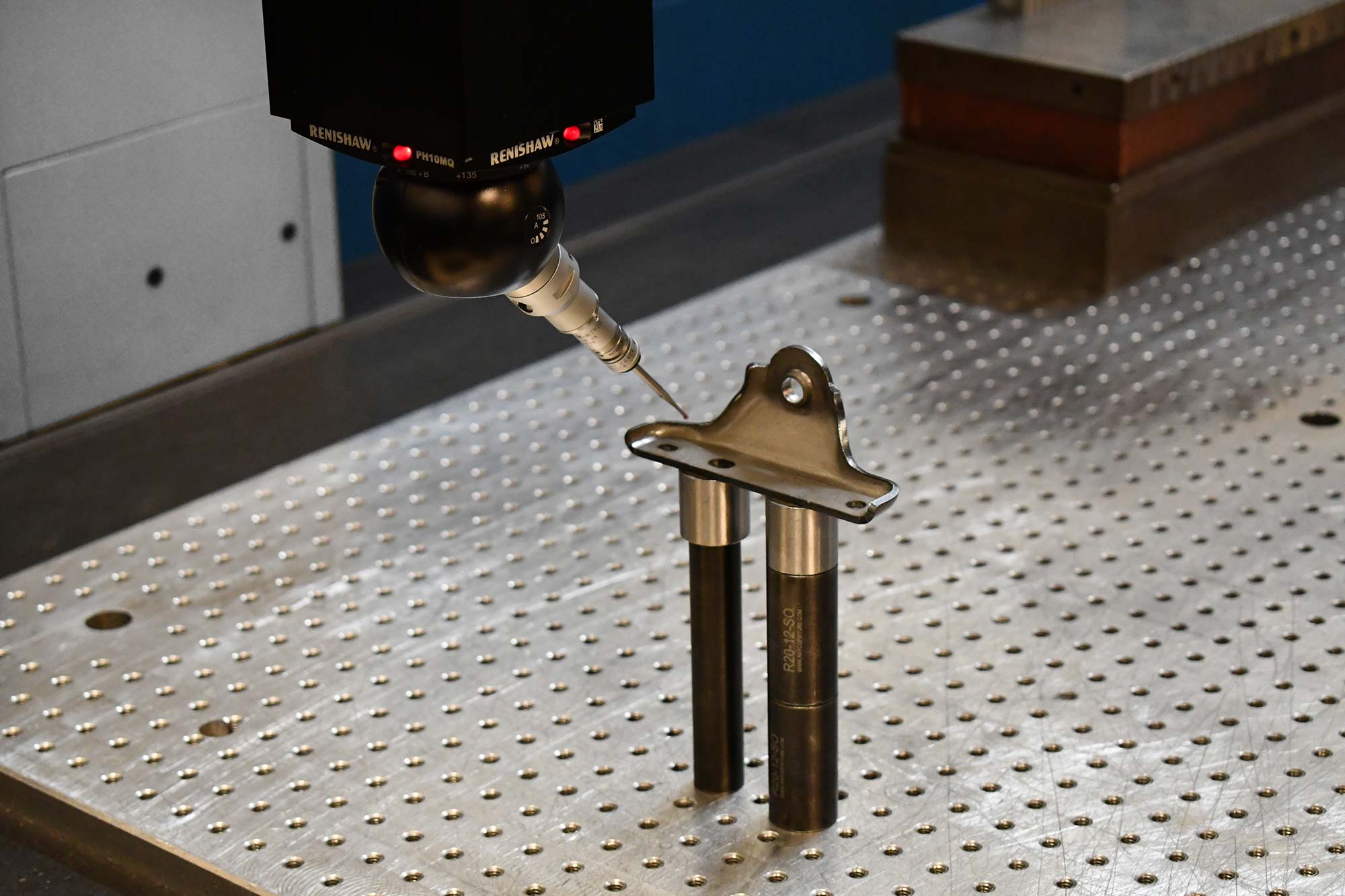

We are committed to supplying our customers with on-time, on-budget delivery with components and assemblies that meet 100% conformance. Not only do we maintain end-to-end traceability, but we back our work with state-of-the-art inspection equipment, data collection and electronic reporting. IMDS, service part PPAP and pictorial measurement data are included with our thorough inspection report submission.

As an ISO 9001-2015 certified manufacturing business, we undergo both third-party and internal audits on an ongoing basis, and strive for continuous improvement. Customer satisfaction is our highest priority.